Duplex 2507 Stainless Steel Sheet and Plate Supplier

Do you have any questions about our products or are you looking for a professional duplex 2507 stainless steel sheet and plate supplier?

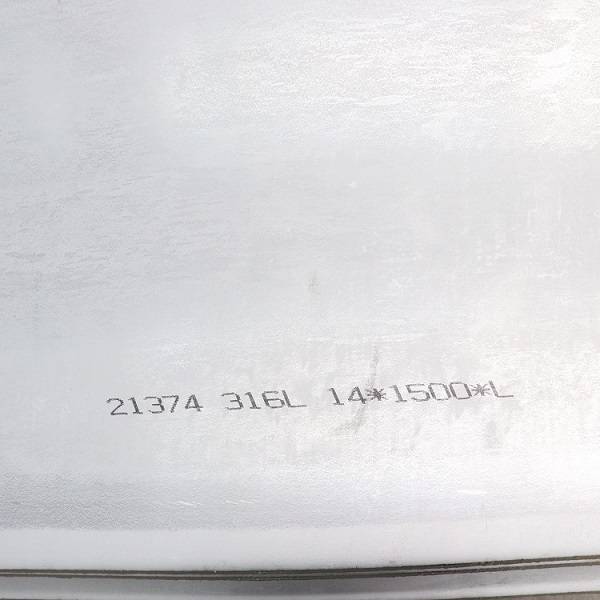

- Specifications: Alloy 2507 (UNS S32750), 1.4410 – X2 Cr Ni MoN 25.7.4, Z3 CN 25.06 Az, Duplex 2507, A240 UNS S32750, DIN/EN 1.4410, ASME SA-240, SAF 2507

- Features: Excellent corrosion resistance, high strength, and superior resistance to chloride stress corrosion cracking, with good weldability and toughness.

- Thickness: 0.2mm – 200mm

- Width: 300mm – 2000mm

- Length: 500mm-12000mm

- Standard: ASTM, JIS, EN, GB

- Finish:2B, BA, 8K, NO.1

- Certification: ISO9001:2015

- MOQ: 2MT

- Payment method: T/T, LC

- Price: Inquiry 2507 stainless steel sheets price now!

Specification of 2507 Stainless Steel Sheets

Ingredients of 2507 Stainless Steel

| 2507 | C% | Si% | Mn% | P% | S% | Ni% | Cr% | Mo% | N |

| ASTM | ≤ 0.03 | ≤ 0.8 | ≤ 1.2 | ≤ 0.035 | ≤ 0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 | 0.24-0.32 |

| EN | ≤ 0.03 | ≤ 1.00 | ≤ 2.00 | ≤ 0.035 | ≤ 0.015 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 | 0.20-0.30 |

| JIS | ≤ 0.03 | ≤ 1.00 | ≤ 1.2 | ≤ 0.035 | ≤ 0.02 | 6.0-8.0 | 11.5-14.5 | 3.0-5.0 | 0.24-0.32 |

| GB | ≤ 0.03 | ≤ 0.08 | ≤ 1.2 | ≤ 0.035 | ≤ 0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 | 0.20-0.32 |

2507 Mechanical Properties in Different Standards

2507 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | 550 | 795 | 15 | 310 | 32 | 310 | 320 |

JIS | 550 | 800 | 15 | 290 | 32 | 310 | 320 |

GB | 550 | 800 | 15 | 290 | 32 | 310 | 320 |

Product Description of 2507 stainless steel sheets and plates

2507 stainless steel plate, as an outstanding representative of duplex stainless steel, combines the advantages of ferrite and austenite, showcasing excellent performance. Its unique alloy composition, including chromium, nickel, molybdenum, and other elements, ensures high strength and outstanding corrosion resistance of the plate. Particularly, by reducing the carbon content, we further enhance its weldability and corrosion resistance, making it suitable for even more demanding environments.

No matter your requirements, we can provide high-quality 2507 stainless steel plates to help your projects succeed. Choose Huaxiao stainless steel supplier for reliability and efficiency.

Classification of Duplex Stainless Steel Sheets

- Cr18 Duplex Stainless Steel: Contains 18% chromium, 5%-8% nickel; offers high strength, corrosion resistance, and good weldability, ideal for marine and chemical applications.

- Cr22 Duplex Stainless Steel: Contains 22% chromium, 6%-8% nickel; has superior strength and corrosion resistance, suitable for petroleum and harsh chemical environments.

- Cr25 Duplex Stainless Steel: Contains 25% chromium, 7%-9% nickel; divided into duplex and super duplex with outstanding strength and corrosion resistance for marine and industrial uses.

- Cr23 Duplex Stainless Steel: Contains 23% chromium, 3%-5% nickel, and some nitrogen and copper; provides excellent corrosion resistance for acidic environments and specialized conditions.

Features of 2507 Stainless Steel Sheets and plates

- Dual-phase structure: 2507 stainless steel combines ferrite and austenite phases, offering excellent resistance to stress corrosion cracking.

- Outstanding corrosion resistance: 2507 stainless steel exhibits strong corrosion resistance in chloride environments, ideal for chemical processing and marine equipment.

- High strength: 2507 stainless steel has high strength and impact toughness, making it suitable for structural and mechanical applications.

- Low thermal expansion: 2507 stainless steel has a low coefficient of thermal expansion and good thermal conductivity, performing well in heat-sensitive applications.

- Excellent post-treatment performance: After solution treatment, 2507 stainless steel offers high tensile strength, yield strength, and elongation, with improved corrosion resistance.

- Good weldability: 2507 stainless steel demonstrates excellent weldability using various methods like shielded metal arc and gas tungsten arc welding.

Application of 2507 Stainless Steel Sheets

1. Chemical and Petroleum Equipment Manufacturing:

- 2507 stainless steel sheet plays a crucial role in chemical and petroleum equipment manufacturing due to its outstanding corrosion resistance and high strength.

- It is commonly used for manufacturing external plates and structural components of key equipment such as reactors and distillation columns, ensuring stable operation in harsh corrosive environments.

2. Construction Applications:

- In the construction industry, the 2507 stainless steel sheet is highly favored for its aesthetic appeal, weather resistance, and corrosion resistance.

- It is often used as exterior wall cladding material, and roofing material, imparting modern aesthetics and long-lasting durability to buildings.

- Additionally, it can be used to fabricate architectural components such as railings and handrails, enhancing both safety and aesthetics.

3. Marine Engineering Structures:

- For offshore oil platforms, ships, and other marine engineering structures, the 2507 stainless steel sheet is widely used due to its excellent resistance to seawater corrosion.

- It can be employed in manufacturing decks for platforms, and hulls for ships, ensuring long-term stability in marine environments.

4. Environmental and Energy Equipment:

- In the field of environmental protection and energy, 2507 stainless steel sheets play a significant role.

- It is commonly used in the manufacturing of exhaust gas treatment equipment, and flue gas desulfurization devices, helping reduce pollutant emissions and protect the environment.

- Additionally, it is utilized in the manufacturing of new energy equipment such as solar and wind energy equipment, ensuring stable operation and long-term use.

Stainless Steel Sheets Supplier --- HUAXIAO

2507 stainless steel sheet demonstrates extensive application value in various fields such as chemical, petroleum, construction, marine engineering, environmental protection, and energy, thanks to its outstanding corrosion resistance, high strength, and good processing performance. Whether utilized in manufacturing key equipment, architectural components, or marine engineering structures, it provides reliable support and protection.

As a professional stainless steel exporter, Huaxiao Metal is committed to providing customers with high-quality products and services. We offer not only standard-sized 2507 stainless steel sheets but also can provide coil packaging according to customer needs to meet different project requirements. Furthermore, we have a wide range of product lines, including other forms of stainless steel products, for you to choose from.

By choosing Huaxiao Stainless Steel, you will receive high-quality, reliable 2507 stainless steel plates, along with professional technical support and after-sales service. We look forward to cooperating with you to create a better future together.

Our competitive Stainless Steel Sheets

We will answer your email in 24 hours!

FAQ

Compared to other stainless steel materials, 2507 stainless steel sheet is more difficult to process. This is due to its high strength and hardness, as well as its high ductility and toughness. Therefore, cutting, drilling, stamping, welding and other processing processes require the use of higher-level tools and equipment, and require more careful and delicate operating skills. In addition, adequate lubrication and cooling are required during processing to avoid problems such as overheating and deformation.

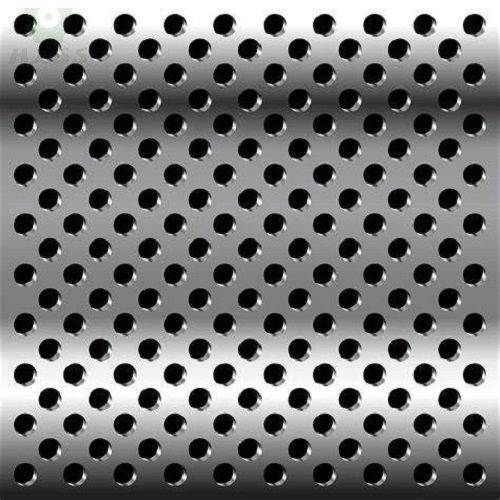

2507 stainless steel plate can be treated by a variety of surface treatment methods to meet different needs, common surface treatment methods include

Sandblasting: Through high-speed injection of abrasive to make the surface form a certain roughness, thus increasing the surface adhesion and aesthetics.

Polishing: Through mechanical grinding and polishing treatment, the surface becomes smooth and shiny, suitable for high-grade products and occasions requiring a high degree of cleanliness.

Mirror: Similar to polishing but more detailed, with a high surface finish, used in demanding applications.

Passivation: Forms a dense oxide film on the surface of stainless steel to improve corrosion resistance.

Spraying: By spraying paint or powder on the surface, it can achieve the effect of anti-corrosion, anti-oxidation and decoration.

Spraying: Forming an ultra-thin nano-ceramic coating on the surface of stainless steel to enhance wear resistance, corrosion resistance, high temperature resistance, etc.

The service life of 2507 stainless steel sheet depends on many factors, such as the environment of use, conditions of use and maintenance. Generally speaking, 2507 stainless steel sheet has a relatively long service life, which can reach decades or even longer. Under the right use environment, it can provide excellent corrosion and wear resistance, reduce the frequency of maintenance and replacement, and save costs. However, the service life of 2507 stainless steel sheet may be shortened under certain extreme use environments, such as high temperature, high pressure, and strong acid. Therefore, when selecting 2507 stainless steel sheet, it is necessary to fully consider the conditions of use and environment and select the appropriate material to ensure its long-term service life.

Here are some ways to protect 2507 stainless steel plates:

- Cleaning: frequent cleaning of the stainless steel sheet surface can prevent the accumulation of dirt and corrosion. It is recommended to use mild detergent and soft cloth for cleaning.

- Avoid Physical Damage: When handling and using stainless steel sheets, avoid scratches, abrasions and impacts that can damage the surface.

- Prevent Chemical Contamination: Do not expose 2507 stainless steel sheet to chemicals such as chlorides, salts and strong acids to avoid corrosion. If contact with these substances is unavoidable, please rinse with water immediately and dry in time.

- Surface Treatment: The use of suitable surface treatment techniques such as electroplating, anodizing, galvanizing, etc. can increase the corrosion resistance and service life of 2507 stainless steel sheet.

- Choose the Right Environment: When using 2507 stainless steel plate, you should choose the right environment and application scenario, and try to avoid high temperature, humidity, acid and alkali conditions to prolong the service life of stainless steel plate.

- In conclusion, proper use and maintenance methods can significantly extend the service life of 2507 stainless steel sheet, reduce maintenance costs, and ensure its excellent performance and appearance.

2205 stainless steel and 2507 stainless steel are both duplex stainless steels with high strength, high corrosion resistance and good toughness. Their main differences are in chemical composition and properties.

- Chemical Composition: 2205 stainless steel has 22% chromium and 5% nickel, while 2507 stainless steel has 25% chromium and 7% nickel, and also contains molybdenum, copper and nitrogen.

- Performance: 2507 stainless steel has higher corrosion resistance, stress corrosion resistance, wear resistance and toughness than 2205 stainless steel, and is also more suitable for use in high temperature, high pressure and strong corrosive environments.

Overall, 2507 stainless steel offers higher performance and a wider range of applications than 2205 stainless steel, but is also correspondingly more expensive. The choice of material depends on the specific environment and needs.