Do you have any questions about our products or are you looking for a professional 310S stainless steel sheets supplier?

310S Stainless Steel Sheet and Plate Supplier

- Specification: DIN 1.4845 S31008, SA213 / TP310S, 310H, 1.4845, ss 310, 310 ss, AISI 310S, Alloy 310/310S/310H (UNS S31000, S31008, S31009), ASTM A 240, ASME SA 240, AMS 5521

- Features: Excellent high-temperature resistance, good corrosion resistance, outstanding mechanical strength, suitable for high-temperature and chemical processing applications.

- Thickness: 0.05mm – 200mm

- Width: 300mm – 2000mm

- Length: 500mm-12000mm

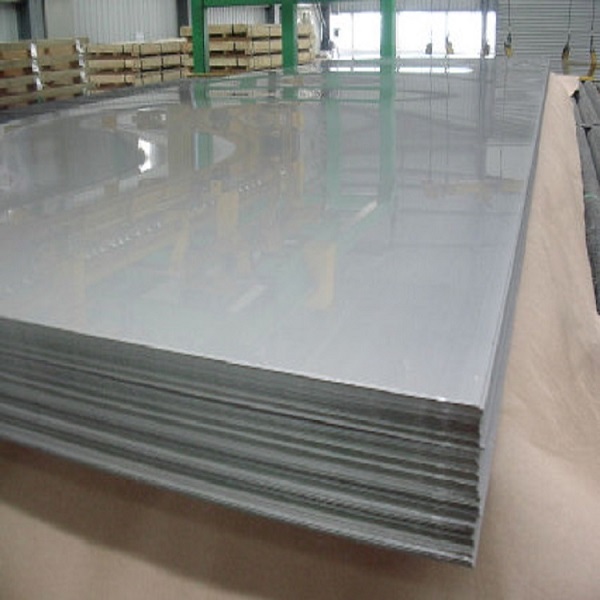

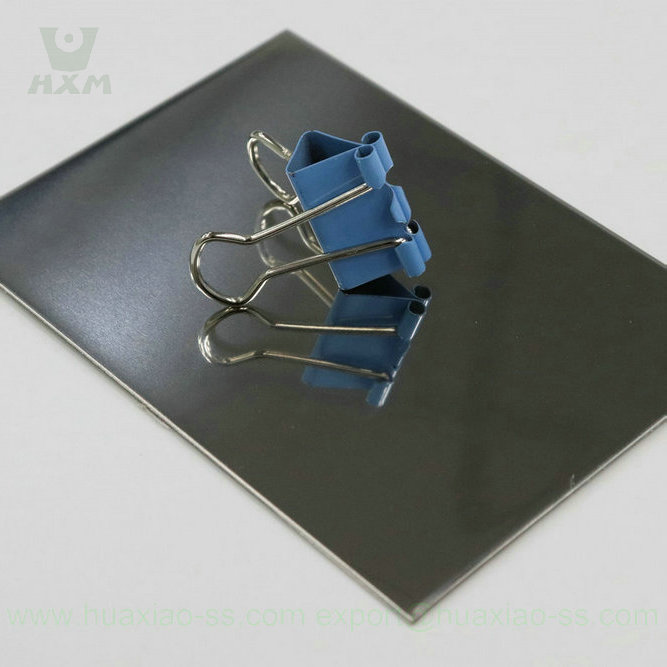

- Finish: 2B, 2D, Black, NO.1, Anneal pickling

- Certification: ISO9001:2015

- MOQ: 2MT

- Payment method: T/T, LC

- Price: Inquiry Grade 310S Stainless Steel Sheets Lastest Price Now!

Production Range of 310s stainless steel sheet and plate

-Cold Rolled 310s Stainless Steel Sheet and Plate, Cold rolled 310s sheets, Cold rolled 310s Plate

- Thickness: 0.05mm – 3.0mm

- Width: 300mm – 2000mm, the narrowed products pls check in strip products

- Length: 1000mm-6000mm

- Finish: 2B, 2D

-Hot Rolled 310s Stainless Steel Sheet and Plate, Hot Rolled 310s Sheet, 310s PMP, 310s CMP

- Thickness: 1.2mm – 200mm

- Width: 300mm – 3200mm

- Length: 500mm – 12000mm

- Finish: Black, NO.1, Anneal pickling

specification of 310s Stainless Steel

310s Grade Description in Different Standard

ISO Name | ASTM | DIN / EN | JIS | GB | Other |

X12CrNi23-12 | S31008 310S | 1.4951 | SUS310S | S31008 | 06Cr25Ni20 0Cr25Ni20 |

310s Grade Chemical Components in Different Standards

310s | C % | Si % | Mn % | P % | S % | Ni % | Cr % | Mo % | N % | Cu % |

ASTM | 0.08 | 1.50 | 2.00 | 0.045 | 0.030 | 19.0-22.0 | 24.0-26.0 | – | – | – |

DIN/EN | 0,10 | 1,50 | 2,00 | 0,045 | 0,015 | 19,0-22,0 | 24,0-26,0 | – | 0,10 | – |

JIS | 0.08 | 1.50 | 2.00 | 0.045 | 0.030 | 19.0-22.0 | 24.0-26.0 | – | – | – |

GB | 0.08 | 1.50 | 2.00 | 0.045 | 0.030 | 19.0-22.0 | 24.0-26.0 | – | – | – |

310s Mechanical Property in Different Standard

310s | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | 205 | 515 | 40 | – | 95 | 217 | – |

JIS | 205 | 520 | 40 | 187 | 90 | – | 200 |

GB | 205 | 515 | 40 | – | 95 | 217 | 220 |

Product Description of 310s stainless steel sheet and plate

310S stainless steel is an austenitic stainless steel known for its excellent high-temperature and corrosion resistance due to its high nickel and chromium content. This allows it to operate stably in high-temperature environments and exhibit excellent oxidation, rust, and acid-alkali resistance. The increased proportion of nickel and chromium not only enhances its temperature resistance but also provides outstanding strength and creep strength at high temperatures.

The carbon content of 310S stainless steel is controlled at a minimum level of 0.08%, significantly lower than the 0.25% carbon content of 310 stainless steel, which greatly improves its rust resistance while slightly reducing its strength. This stainless steel has a high melting point of up to 1470°C but begins to soften at 800°C, so its performance changes within this temperature range need to be considered in design.

To further enhance its performance, 310S stainless steel is alloyed with additives such as molybdenum, tungsten, niobium, and titanium on the basis of chromium and nickel. These additives not only strengthen its high-temperature strength but also maintain its face-centered cubic structure, ensuring stability and durability at high temperatures. Although its low and high melting points make the smelting process relatively complex, this does not affect the excellent performance of 310S stainless steel in high-temperature applications.

Features of 310s Stainless Steel Sheets&Plates

- High Temperature Stability: 310S stainless steel plate can maintain its stable performance in high-temperature environments, exhibiting excellent high-temperature resistance. This is mainly due to its high nickel and chromium content, allowing it to operate continuously at temperatures up to 1150°C.

- Corrosion Resistance: 310S stainless steel plate has excellent corrosion resistance to oxidizing acids, sulfuric acid, and nitric acid, making it widely used in chemical, petroleum, and food processing industries.

- Good Mechanical Properties: This stainless steel plate has good strength and ductility, meeting the requirements of various engineering projects.

- Oxidation Resistance: 310S stainless steel plate can resist oxidation and fading under high-temperature conditions, keeping its surface bright and new in high-temperature environments.

- Ease of Machining and Welding: 310S stainless steel plate has good machinability and weldability, facilitating various shaping and joining processes.

- High Chromium-Nickel Content: The chromium and nickel content of 310S stainless steel plate is high, namely 25Cr-20Ni, which provides it with better creep strength.

Application of 310s Stainless Steel Sheets&Plates

High-Temperature Furnaces

310s stainless steel plate can withstand high temperatures up to 1100 ℃, so it is often used in the manufacture of high-temperature furnaces, such as electric furnace heating elements, kilns, and heat treatment furnaces.

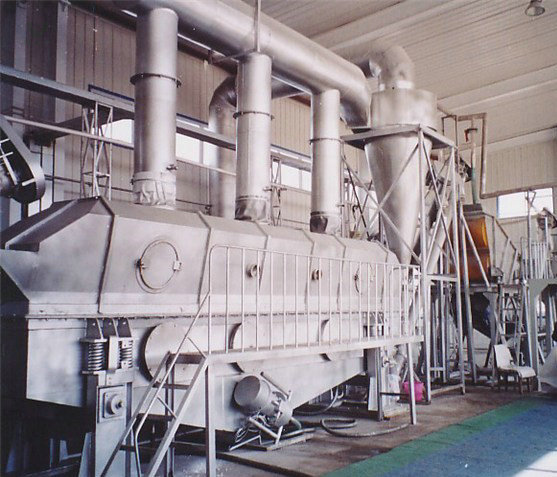

Chemical Equipment

310s stainless steel plate has the properties of acid resistance, alkali resistance, and high-temperature resistance, and is widely used in the manufacture of chemical equipment, such as pickling equipment, storage tanks, reactors, etc.

Aero-Engine Parts

310s stainless steel plate has very good high-temperature strength and oxidation resistance and is widely used in the manufacture of aero-engine parts, such as turbine blades, combustion chambers, nozzles, etc.

Sugar Equipment

Sugar equipment requires high corrosion performance of materials, 310s stainless steel plate can meet this demand and is widely used in the manufacture of sugar equipment, such as steam boilers, honey tanks, evaporators, etc.

Salt Production Equipment

310s stainless steel plate has a good corrosive performance to brine and seawater and is widely used in the manufacture of salt production equipment, such as salt drying ovens, salt crystals, salt concentrators, etc.

Pharmaceutical Equipment

Pharmaceutical equipment requires high corrosion resistance of the material, 310s stainless steel plate can meet this demand and is widely used in the manufacture of pharmaceutical equipment, such as reactors, drying boxes, filters, etc.

Ship Fittings

Ship fittings require good corrosion resistance, 310s stainless steel plate can meet this demand, and is widely used in the manufacture of ship fittings, such as marine piping, radiators, pumps, etc.

Our competitive Stainless Steel Sheets

We will answer your email in 24 hours!

FAQ

- Carbon Content: The carbon content of 310 stainless steel is 0.25%, while that of 310S stainless steel is lower, with a minimum of 0.08%.

- Corrosion Resistance: Due to the difference in carbon content, 310S exhibits superior corrosion resistance compared to 310, especially in high-temperature environments.

- Processing Performance: 310S, owing to its lower carbon content, may have better processing performance.

- Carbon Content: SS 310S is a low-carbon version of SS 310, with a lower carbon content, which helps improve its corrosion resistance and reduce the risk of embrittlement. Meanwhile, 310H has a higher carbon content, specifically designed to enhance creep strength and creep rupture strength.

- Applications: SS 310S is primarily used in applications requiring good corrosion resistance and high-temperature stability, such as furnace manufacturing and heat treatment equipment. On the other hand, 310H is more suitable for applications under high-temperature conditions, such as the heat treatment industry and environments containing concentrated acids.

- Mechanical Properties: Although both SS 310S and 310H have good mechanical properties, 310H may have higher strength and creep strength due to its higher carbon content.

- Processing Techniques: SS 310S can be hardened by cold working, although cold working is not common. While 310H can also undergo cold working, prolonged cold working may result in carbon precipitation.

310S stainless steel is not considered food-grade stainless steel. Although 310S stainless steel exhibits good oxidation resistance, corrosion resistance, and high-temperature stability, and is commonly used in high-temperature environments, chemical, petroleum, and other fields, it is not explicitly designated as food-grade stainless steel.

310 stainless steel typically does not exhibit significant magnetism. Austenitic stainless steels, such as 310, often have low levels of ferromagnetic materials, making them difficult or unable to be attracted by magnets. However, stainless steel may show some magnetism due to fluctuations in composition during the smelting process or differences in processing conditions, but this does not imply that it is an inferior product.

Processing 310S stainless steel plates is moderately challenging. Its high yield point and tensile strength require attention to equipment strength and wear resistance during processing. Additionally, its low thermal conductivity necessitates the selection of lubricating oils with good cooling performance. However, overall, 310S stainless steel plates can be processed using conventional cold and hot working techniques.

The service life of 310S stainless steel plates is influenced by various factors such as the quality of the plates, operating environment, and conditions of use, hence an exact service life cannot be specified. However, under favorable conditions, its service life can extend to several years or even longer.

- Regular Cleaning: Remove surface dirt to prevent corrosion.

- Rust Prevention Treatment: Use rust inhibitors or coatings to protect the surface.

- Environmental Control: Avoid prolonged exposure to damp and corrosive environments.

- Prevent Physical Damage: Minimize scratches, impacts, and other mechanical damage.