Do you have any questions about our products or are you looking for a professional 321 stainless steel sheets supplier?

321 Stainless Steel Sheet and Plate Supplier

- Specifications: AMS 5510, ASTM A240 1.4541, SA 666, S32100, ASTM A480, SAE 30321, 12X18H9T, 321S20, X12CrNiTi18.9, SUS 321

- Features: High corrosion resistance, good weldability, excellent formability, and strong mechanical properties

- Thickness: 0.05mm – 200mm

- Width: 600mm – 2000mm

- Length: 500mm-12000mm

Certification: ISO9001:2015

MOQ: 2MT

Payment method: T/T, LC

Price: Inquiry Grade 321 Stainless Steel Sheets Lastest Price Now!

321 Stainless Steel sheet and plate Data Sheet

321 Grade Description in Different Standard

ISO Name | ASTM | DIN / EN | JIS | GB | Other |

X6CrNiTi18-10 | S32100 321 | 1.4541 | SUS321 | S32168 | 06Cr18Ni11Ti 0Cr18Ni10Ti |

321 Mechanical Properties in Different Standard

321 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | 205 | 515 | 40 | – | 95 | 217 | – |

JIS | 205 | 520 | 40 | 187 | 90 | – | 200 |

GB | 205 | 520 | 40 | – | 95 | 217 | 220 |

321 Physical Properties in Different Standard

| 321 | Density (g/cm³) | Melting point (℃) | Thermal conductivity (W/m-K) | Coefficient of thermal expansion (10^-6/K) |

| ASTM | 7.93 | 1398-1420 | 16.3 | 16.5 |

| JIS | 7.93 | 1398-1420 | 16.3 | 16.5 |

| EN | 7.93 | 1398-1420 | 16.3 | 16.5 |

| GB | 7.93 | 1398-1420 | 16.3 | 16.5 |

Production Range of 321 stainless steel sheet and plate

-Cold Rolled 321 Stainless Steel Sheet and Plate, Cold rolled 321 sheets, Cold rolled 321 Plate

- Thickness: 0.05mm – 3.0mm

- Width: 600mm – 2000mm, the narrowed products pls check in strip products

- Length: 1000mm-6000mm

- Finish: 2B, 2D

-Hot Rolled 321 Stainless Steel Sheet and Plate, Hot Rolled 321 Sheet, Hot Rolled 321 Plate,321 PMP, 321 CMP

- Thickness: 1.2mm – 200mm

- Width: 600mm – 3200mm

- Length: 500mm – 12000mm

- Finish: Black, NO.1, Anneal pickling

Product Description of 321 stainless steel sheet and plate

304 and 321 stainless steels both belong to the 300 series and exhibit similar corrosion resistance. However, in high-temperature environments (500-600 degrees Celsius), 321 stainless steel sheets and plate has advantages. 321H, a special type of 321 stainless steel, has a higher carbon content, similar to China’s 1Cr18Ni9Ti, and its resistance to intergranular corrosion is strengthened by the addition of titanium elements.

In the early stages of stainless steel manufacturing, it was challenging to reduce the carbon content in steel due to technological limitations, necessitating the supplementation of other elements such as titanium. With technological advancements, it is now possible to produce low-carbon and ultra-low-carbon stainless steels, whose performance is comparable to 1Cr18Ni9Ti, 321H, or 321 in terms of heat resistance.

321 stainless steel is a Ni-Cr-Mo type stainless steel, with overall performance similar to 304, but with the addition of titanium elements, enhancing high-temperature strength and resistance to intergranular corrosion. Additionally, the addition of titanium effectively controls the formation of chromium carbides. This stainless steel exhibits excellent wear resistance in various concentrations of amino acids and temperatures, especially in oxidizing environments. Therefore, 321 stainless steel is widely used in the manufacture of wear-resistant linings, communication pipelines, and acid containers.

Features of 321 Stainless Steel Sheets&Plates

- Corrosion Resistance: 321 stainless steel plates exhibit excellent corrosion resistance in air or chemical corrosive media.

- Heat Resistance: This stainless steel possesses good oxidation resistance and can operate stably for long periods in high-temperature environments. Its operating temperature range typically ranges from -196°C to 800°C.

- Machinability: 321 stainless steel plates have good forgeability, ductility, and weldability, making them easy to process into various shapes.

- Mechanical Properties: It has good mechanical properties, able to withstand high static pressure, and exhibits good dimensional stability.

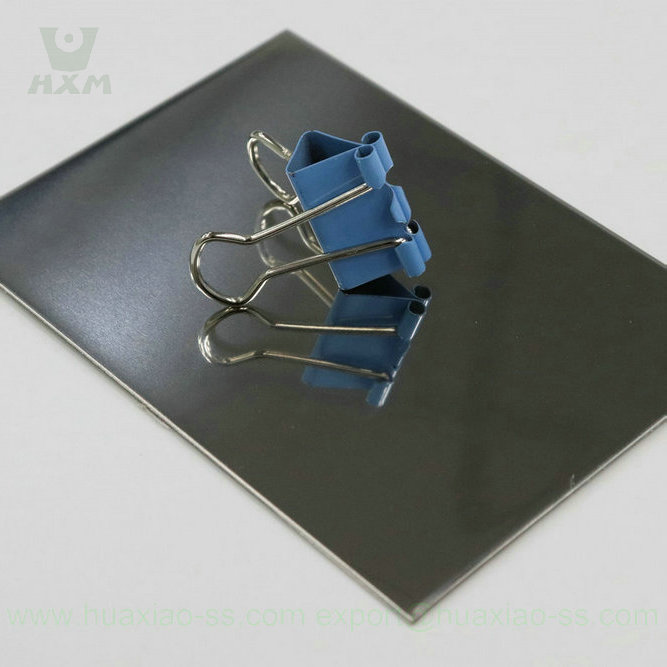

- Aesthetic Appeal: The surface quality of 321 stainless steel plates is excellent, presenting an elegant appearance.

- Excellent Wear Resistance: 321 stainless steel plates demonstrate good wear resistance in various concentrations of amino acids and temperatures, particularly in oxidizing environments.

- Intergranular Corrosion Resistance: Due to the addition of titanium elements, 321 stainless steel plates possess outstanding resistance to intergranular corrosion.

Application of 321 Stainless Steel Sheets& Plates

Petroleum and Chemical Industry

Because of its resistance to corrosion, 321 stainless steel sheet is widely used in the manufacture of equipment such as pipelines, heat exchangers, boilers, reactors and storage tanks in the oil, gas and chemical industries.

Food and Pharmaceutical Industry

321 stainless steel plate is very resistant to corrosion and oxidation, so it is used in the manufacture of equipment such as pharmaceutical equipment, food processing equipment, storage tanks, and conveying pipelines.

Aerospace Industry

321 stainless steel plate has excellent high-temperature resistance and weldability, so it is widely used in the manufacture of aircraft engines and gas turbines, and structural parts of aircraft.

Automotive Industry

321 stainless steel plate is used in the manufacture of automotive exhaust, intake manifold, and turbocharger components, which need to have high temperature and corrosion resistance.

Paper and Textile Industry

321 stainless steel sheet is used in the manufacture of pipes and components for equipment such as dryers, chimneys, boiler tubes, and heaters, which need to have high temperature and corrosion resistance.

Why Choose Huaxiao

Rich Product Line

As a professional stainless steel supplier, Huaxiao Metal is not only a 321 stainless steel plate supplier but also provides various stainless steel products: bars, coils, narrow strips in various forms, and different materials, which can meet the needs of different customers.

High Quality Stainless Steel Materials

As a reliable stainless steel supplier, Huaxiao Metal will carefully check each batch of goods and only use stainless steel material that has been strictly inspected to ensure the quality and stable performance of the products.

Flexible Production Capacity

Huaxiao Metal stainless steel suppliers cooperate with several professional stainless steel factories. They have advanced production equipment and efficient production process and can customize production according to customer's needs to meet different production requirements.

Excellent After-Sales Service

As a trusted stainless steel product supplier, Huaxiao Metal provides excellent after-sales service, including technical support and product consultation, to ensure that customers get timely help and solutions when using stainless steel products.

FAQ

- Alloy Composition: 321 stainless steel contains titanium elements, while 316 stainless steel contains molybdenum elements. This gives 321 better high-temperature resistance, while 316 exhibits superior corrosion resistance.

- Mechanical Properties: Due to the presence of titanium elements in 321 stainless steel, its strength and hardness are relatively higher, but its plasticity and toughness are slightly lower compared to 316 stainless steel. 316 stainless steel, on the other hand, offers good machinability and ductility, making it easy to process into various shapes.

- Applications: 321 stainless steel is commonly used in high-temperature environments due to its excellent high-temperature resistance, such as in aircraft exhaust pipes, boilers, and heat exchangers. Meanwhile, 316 stainless steel, known for its outstanding corrosion resistance, is more suitable for applications in chemical products, marine environments, and other corrosive environments.

- Price: Generally, the price of 321 stainless steel is slightly higher than that of 316 stainless steel, mainly due to the presence of rare elements such as titanium.

- Alloy Composition: 321 stainless steel contains titanium (Ti) elements, while 304 stainless steel does not contain titanium. The addition of titanium helps improve the high-temperature resistance and corrosion resistance of 321 stainless steel.

- Heat Resistance: In high-temperature environments (typically between 500-600 degrees Celsius), 321 stainless steel exhibits better heat resistance. This gives it an advantage in high-temperature applications.

- Corrosion Resistance: Although both 321 and 304 have excellent corrosion resistance, in certain specific environments, 321 may exhibit slightly stronger corrosion resistance.

- Mechanical Properties: Both have similar mechanical properties, but 321’s high-temperature strength and resistance to intergranular corrosion may be slightly superior to 304.

The surface treatment of 321 stainless steel sheets includes the following:

- 2B: The stainless steel sheet with 2B surface treatment has a smooth and glossy surface, which is suitable for manufacturing deep-drawn parts and products with high appearance requirements.

- BA: BA surface treatment is made of stainless steel plate with 2B surface treatment after continuous electrolytic polishing and surface treatment. BA surface treatment stainless steel plate has a smooth and lustrous surface, suitable for manufacturing high-grade kitchenware and decorative materials, etc.

- NO.1: NO.1 surface treatment is made in the hot rolling process, the surface is relatively rough, suitable for manufacturing some mechanical parts that do not require a surface finish.

- HL: HL surface treatment is made by grinding on the basis of NO.2D surface treatment, and the surface shows a fine rough surface with longitudinal abrasion marks, which is suitable for manufacturing decorative materials and metal products, etc.

- NO.3: NO.3 surface treatment is polished again on the basis of HL surface treatment to make the surface more flat and smooth, suitable for the manufacture of high-grade decorative materials.

The heat treatment methods of 321 stainless steel plate include the following:

- Solution Annealing: At a temperature of 800~900℃, the 321 stainless steel plate is heated for a period of time and then cooled, which can eliminate the residual stress in the material and improve the machinability and ductility of the material.

- Water Quenching and Annealing: 321 stainless steel plate is heated at high temperature and then cooled rapidly, which can increase the hardness and strength of the material.

- Hot Working: cold working or hot working of 321 stainless steel plate at high temperature can improve the mechanical properties and ductility of the material.

- Constant Temperature Quenching: 321 stainless steel plate is heated at high temperature and then quenched after being kept at constant temperature for a period of time, which can improve the strength and hardness of the material while maintaining a certain degree of toughness.

- Tempering Treatment: heating the 321 stainless steel plate at high temperature for a period of time and then cooling it at an appropriate rate can improve the plasticity and toughness of the material and reduce the brittleness of the material.

The service life of 321 stainless steel plate depends on a variety of factors, such as the use environment, stress state, surface treatment quality, use conditions, etc. Generally speaking, under normal use, the service life of 321 stainless steel plate can reach more than 20 years. But if in special use conditions, such as high temperature and pressure, strong corrosive environment, the service life may be reduced accordingly. Therefore, when using 321 stainless steel plate, you need to develop a corresponding use and maintenance plan according to the specific situation in order to extend its service life.

- Control of Usage Environment: Avoid using in harsh environments such as high temperature, strong acids, and alkalis to reduce corrosion and damage to stainless steel.

- Regular Cleaning and Maintenance: Regularly remove stains and impurities from the surface of stainless steel to keep it clean and dry, preventing corrosion and oxidation.

- Proper Material Selection and Design: Choose appropriate 321 stainless steel materials and design structures according to specific usage environments and requirements to enhance corrosion resistance and mechanical performance.

- Standardized Operation and Maintenance: Follow standardized operation and maintenance procedures to prevent stainless steel damage and deterioration caused by improper use and maintenance.