Do you have any questions about our products or are you looking for a professional 430 stainless steel sheets supplier?

430 Stainless Steel Sheets and Plates Supplier

Specifications:DIN 1.4016, SUS 430, 430 BA, ASTM A240, AISI 430, SS 430 Sheet, Stainless Steel 430 Sheets, Alloy 430 , UNS S43000

Features: Good corrosion resistance and excellent formability, with magnetic properties and high resistance to oxidation.

Thickness: 0.05mm – 200mm; Width: 600mm – 2000mm; Length: 500mm-12000mm

Standard: ASTM, JIS, EN, GB, AISI

Finish: 430 2B Finish, 2D, Black, NO.1, #4 Finish, 430 Annealed, 430-BA SS sheet

Certification: ISO9001:2015

MOQ: 2MT

Payment method: T/T, LC

Price: Inquiry Factory Price 430 stainless steel sheets Now

430 Stainless Steel Data Sheets

430 Grade Stainless Steel Description in Different Standard

ISO Name | ASTM | DIN / EN | JIS | GB | Other |

X6Cr17 | S43000 430 | 1.4016 | SUS430 | 10Cr17 1Cr17 |

430 Grade Stainless Steel Chemical Components in Different Standard

430 | C % | Si % | Mn % | P % | S % | Ni % | Cr % | Mo % | N % | Cu % |

ASTM | 0.12 | 1.00 | 1.00 | 0.04 | 0.030 | 0.75 | 16.0-18.0 | – | – | |

DIN/EN | 0,08 | 1,00 | 1,00 | 0,04 | 0,015 | – | 16,0-18,0 | – | – | – |

JIS | 0.12 | 0.75 | 1.00 | 0.04 | 0.030 | – | 16.0-18.0 | – | – | – |

GB | 0.12 | 1.00 | 1.00 | 0.04 | 0.030 | 0.75 | 16.0-18.0 | – | – | – |

430 Mechanical Properties in Different Standard

430 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | 205 | 450 | 22 | – | 89 | 183 | – |

JIS | 205 | 450 | 22 | 183 | 88 | – | 200 |

GB | 205 | 450 | 22 | – | 89 | 183 | 200 |

430 Physical Properties in Different Standard

| 430 | Density (g/cm³) | Melting point (℃) | Thermal conductivity (W/m-K) | Coefficient of thermal expansion (10^-6/K) |

| ASTM | 7.7 | 1425-1510 | 24.2 | 10.4 |

| JIS | 7.7 | 1425-1510 | 25.1 | 10.4 |

| EN | 7.7 | 1425-1510 | 25 | 10.4 |

| GB | 7.7 | 1425-1510 | 26 | 10.4 |

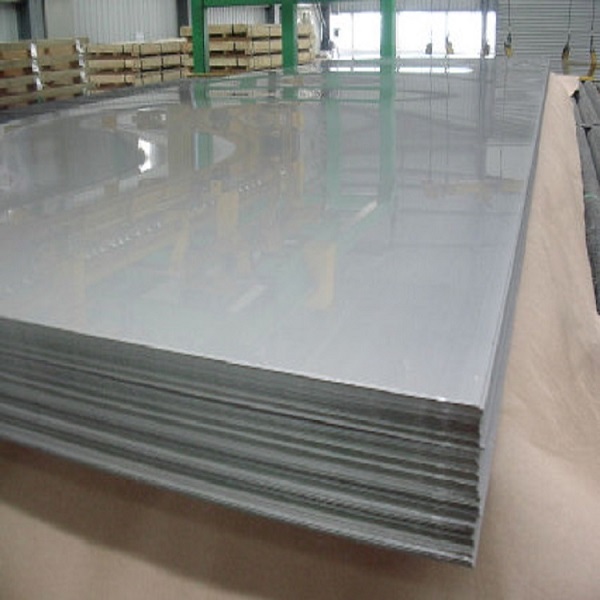

Huaxiao Stainless inventory now includes Grade 430 Stainless Steel (UNS S43000) in sheet coil, sheet, plate,(round)bar, processed flat bar products.

Production Range of 430 stainless steel sheet and plate

-430 Cold Rolled Stainless Steel Sheet and Plate, Cold rolled 430 sheets, Cold rolled 430 Plate

- Thickness: 0.05mm – 3.0mm

- Width: 600mm – 2000mm, the narrowed products pls check in strip products

- Length: 1000mm-6000mm

- Finish: 2B, 2D

-430 Hot Rolled Stainless Steel Sheet and Plate, Hot Rolled 430 Sheet, 430 PMP, 430 CMP

- Thickness: 1.2mm – 200mm

- Width: 300mm – 3200mm

- Length: 500mm – 12000mm

- Finish: Black, NO.1, Anneal pickling

Product Description of 430 stainless steel sheet

430 stainless steel sheet is a ferritic stainless steel sheet with chromium content of about 16%-18%, which is a low alloy steel. It has excellent corrosion resistance, toughness and mechanical strength, and can be used in a range of different products such as kitchen utensils, furniture, construction materials, automotive parts, etc.

430 stainless steel has much better thermal conductivity than austenite. Compared with austenite, its thermal growth coefficient is much greater. 430 stainless steel sheet is easy to form and weld during thermal processing, has a smooth surface, is easy to clean, and is relatively inexpensive, so it is widely used in a number of mass-produced products. However, it is relatively weak in corrosion resistance and cannot be used in strong acid and alkali environments for long periods of time, and is prone to deformation at high temperatures.

430F is added to lathes, nuts and bolts, mainly into this tip of the metal operation. 430LX adds Ti or Nb to 430 metal to reduce C material and improve machinability and weldability. It is mainly used in hot water tanks, hot water distribution systems and sanitary products, household appliances, bicycle flywheels, etc.

Features of 430 Stainless Steel Sheets&Plates

- Excellent corrosion resistance: 430 stainless steel sheet is a ferritic stainless steel with excellent corrosion resistance, especially in atmospheric, water, and certain chemical media. This makes it an ideal choice for many applications such as construction, automotive, and home decoration.

- Outstanding machinability: 430 stainless steel sheet has good machinability and can be formed, cut, and welded through various processing methods to meet the manufacturing needs of various complex shapes and structures.

- Good toughness and ductility: This stainless steel sheet has good toughness and ductility, allowing it to deform to some extent when subjected to external forces without easy fracture. This makes it perform well in applications where it needs to bear certain loads or impacts.

- Lower thermal conductivity: Compared to austenitic stainless steel, 430 stainless steel sheet has lower thermal conductivity. This means that it can maintain good stability in high or low temperature environments, without significant deformation or performance changes due to temperature fluctuations.

- Relatively lower cost: Compared to some other stainless steels, the cost of 430 stainless steel sheet is relatively lower. This makes it more competitive in applications where economy and practicality are pursued.

Application of 430 Stainless Steel Sheets&Plates

Construction Industry

430 stainless steel sheet is commonly used in outdoor construction materials, such as metal roofing, wall panels, window and door frames, railings, flooring, etc. because it has good resistance to weathering and corrosion resistance.

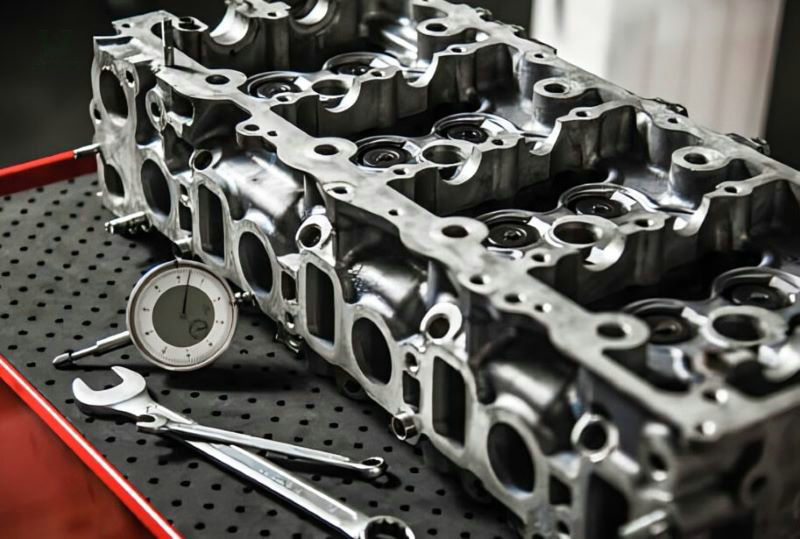

Automotive Industry

430 stainless steel sheet is widely used in automotive exhaust systems and other automotive parts, such as cylinder heads, exhaust pipes, mufflers, fuel filters, etc., because of its heat and oxidation resistance properties.

Chemical Industry

430 stainless steel plate is often used in chemical storage tanks, pipes, fittings, etc., because it has the advantages of corrosion resistance, high-temperature resistance, wear resistance, etc.

Electronic Industry

430 stainless steel plate is commonly used in the production of electronic components shells, terminal blocks, battery cells, etc. because it has electrical insulation properties, corrosion resistance, and high-temperature stability properties.

Stainless Steel Sheets Supplier — HUAXIAO

Thank you wholeheartedly for taking the time to read this introduction to 430 stainless steel sheet. Through reading, I believe everyone has gained a clearer understanding of the characteristics and applications of 430 stainless steel sheet, and I hope this information will be positively influential in your future work and life. As a leading expert in stainless steel export industry, Huaxiao Metal always adheres to the principle of customer first, committed to providing excellent 430 stainless steel sheet products to meet your diverse needs. If you have any questions or requirements, please feel free to contact us, and we will be dedicated to serving you.

Our competitive Stainless Steel Sheets

We will answer your email in 24 hours!

FAQ

- Chemical composition: 430 stainless steel sheet contains 16% to 18% chromium and trace amounts of nickel, manganese, and other elements, while 304 stainless steel sheet contains around 18% chromium, around 8% nickel, and small amounts of carbon and other elements.

- Physical properties: 430 stainless steel sheet is harder, more brittle, and more prone to wear than 304 stainless steel sheet. However, its corrosion resistance is relatively poor compared to 304 stainless steel sheet.

- Stability: 304 stainless steel sheet is in the austenite phase, making it more stable than 430 stainless steel sheet.

- Toughness: 304 stainless steel sheet has stronger toughness and is less prone to fracture than 430 stainless steel sheet.

- Thermal conductivity: The ferritic structure of 430 stainless steel sheet gives it better thermal conductivity than the austenitic structure of 304 stainless steel sheet.

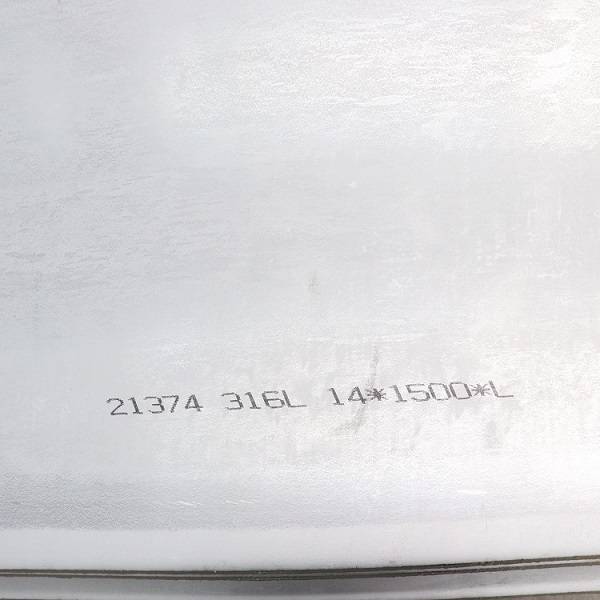

- Chemical composition: 430 stainless steel sheet primarily contains chromium and does not contain or contains only trace amounts of nickel, while 316 stainless steel sheet contains higher levels of chromium and nickel, with the addition of molybdenum. This makes the chemical composition of 316 stainless steel sheet more complex.

- Corrosion resistance: Due to the addition of molybdenum, 316 stainless steel sheet exhibits better corrosion resistance than 430 stainless steel sheet, particularly in seawater and other corrosive environments. While 430 stainless steel sheet also has some corrosion resistance, it may not perform as well as 316 stainless steel sheet in certain harsh environments.

- Cost: Generally, 316 stainless steel sheet has a higher cost compared to 430 stainless steel sheet due to its higher alloy content and more complex production process. On the other hand, 430 stainless steel sheet is relatively cheaper and suitable for applications where cost is a significant factor.

No, 430 stainless steel sheet does not meet food-grade standards. Although it is a type of stainless steel material, it does not comply with the requirements of the national standard GB 9684 and therefore cannot be certified as food-grade stainless steel. When selecting food-grade stainless steel, it is recommended to use materials such as 304 or 316 that comply with national standards.

The service life of 430 stainless steel plate depends on a variety of factors, such as the use environment, operation methods, maintenance and other factors. In general, the service life of 430 stainless steel plate is relatively short, usually about 5-10 years, but the specific life expectancy needs to be assessed on a case-by-case basis. In the process of use, regular inspection, cleaning and maintenance can extend the service life of 430 stainless steel plate.

- Maintain dryness: Avoid prolonged exposure to moist environments to reduce the possibility of corrosion.

- Avoid scratching: Prevent contact with sharp objects during use to minimize surface scratches and damage.

- Regular cleaning: Clean the surface regularly with mild detergent and a soft cloth to remove stains and dust.

- Avoid exposure to direct sunlight: Try to avoid prolonged exposure to strong sunlight to prevent damage from UV radiation.

- Proper storage: When storing, keep the area dry, well-ventilated, and avoid contact with chemical substances.