Do you have any questions about our products or are you looking for a professional perforated stainless steel sheets supplier?

Perforated Stainless Steel Sheet and Plate Supplier

- Specification: ASTM 304, UNS S30400, ASTM 316, UNS S31600, ASTM 409, UNS S40900, ASTM 430, UNS S43000, EN 1.4301, EN 1.4401, JIS SUS304, JIS SUS316.

- Features: Provides strength, corrosion resistance, and ventilation, commonly used in architectural, industrial, and filtration applications.

- Thickness: 0.035mm – 12mm

- Width: 100mm – 2000mm

- Length: 500mm-12000mm

- Finish: 2B, 2D, Black, NO.1, Anneal pickling

- Material Grade: AISI grades 304, 310, 321, 410, 430, and Duplex (2205, 2507), etc.

- Available Stock Sizes: 1ft x 4ft, 2ft x 4ft, 4ft x 4ft, 4ft x 8ft, or Cut to Size

- MOQ: 2MT

- Payment method: T/T, LC

- Price: Inquiry Now

Perforated Stainless Steel Sheets Data Sheet

Main Grade Description in Different Standard

ASTM | DIN / EN | JIS | GB | ISO Name | Other |

1.4372 | SUS201 | S35350 | X12CrMnNiN17–7-5 | J1 L1 LH 201J1 | |

S20200 202 | 1.4373 | SUS202 | S35450 | X12CrMnNiN18–9-5 | 202 L4, 202 J4, 202 J3 |

S30100 | 1.4319 | SUS301 | S30110 | X5CrNi17–7 | 06Cr17Ni7 |

S30400 | 1.4301 | SUS304 | S30408 | X5CrNi18-10 | 06Cr19Ni10 |

S31008 | 1.4951 | SUS310S | S31008 | X12CrNi23-12 | 06Cr25Ni20 |

S31603 | 1.4404 | SUS316L | S31603 | X2CrNiMo17-12-2 | 022Cr17Ni12Mo2 |

S40900 | – | SUH409 | S11168 | X5CrTi12 | 0Cr11Ti |

S40910 | 1.4512 | SUH409L | S11163 | X2CrTi12 | 00Cr11Ti |

S41008 | 1.4000 | SUS410S | S11306 | X6Cr13 | – |

S43000 | 1.4016 | SUS430 | 10Cr17 | X6Cr17 | 1Cr17 |

S32205 | – | – | S22053 | – | – |

S32750 | 1.441 | – | S25073 | X2CrNiMoN25–7-4 | 00Cr25Ni7Mo4N |

Main-Grade Mechanical Properties in Different Standard

| 201 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

| ASTM | 260 | 515 | 40 | – | 95 | 217 | – |

| JIS | 275 | 520 | 40 | 241 | 100 | – | 253 |

| GB | 205 | 515 | 30 | - | 99 | – | - |

| 202 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

| ASTM | 260 | 620 | 40 | – | – | 241 | – |

| JIS | 275 | 520 | 40 | – | 95 | 207 | 218 |

| GB | – | – | – | – | – | – | – |

| 301 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

| ASTM | 205 | 515 | 40 | – | 95 | 217 | – |

| JIS | 205 | 520 | 40 | 207 | 95 | – | 218 |

| GB | 205 | 515 | 40 | – | 95 | 217 | 218 |

| 304 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

| ASTM | 205 | 515 | 40 | – | 92 | 201 | – |

| JIS | 205 | 520 | 40 | 187 | 90 | – | 200 |

| GB | 205 | 515 | 40 | – | 92 | 201 | 210 |

| 310S | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

| ASTM | 205 | 515 | 40 | – | 95 | 217 | – |

| JIS | 205 | 520 | 40 | 187 | 90 | – | 200 |

| GB | 205 | 515 | 40 | – | 95 | 217 | 220 |

| 316L | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

| ASTM | 170 | 485 | 40 | – | 95 | 217 | – |

| JIS | 175 | 480 | 40 | 187 | 90 | 200 | |

| GB | 170 | 485 | 40 | – | 95 | 217 | 220 |

| 409 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

| ASTM | – | – | – | – | – | – | – |

| JIS | 175 | 360 | 22 | 162 | 80 | – | 175 |

| GB | – | – | – | – | – | – | – |

| 409L | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

| ASTM | 170 | 380 | 20 | – | 88 | 179 | – |

| JIS | 175 | 360 | 25 | 162 | 80 | – | 175 |

| GB | 170 | 380 | 20 | – | 88 | 179 | 200 |

| 410S | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

| ASTM | 205 | 415 | 22 | – | 89 | 183 | – |

| JIS | 205 | 410 | 20 | – | 88 | 183 | 200 |

| GB | 205 | 415 | 20 | – | 89 | 183 | 200 |

| 430 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

| ASTM | 205 | 450 | 22 | – | 89 | 183 | – |

| JIS | 205 | 450 | 22 | 183 | 88 | – | 200 |

| GB | 205 | 450 | 22 | – | 89 | 183 | 200 |

| 2205 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRC ≤ | HBW ≤ | HV ≤ |

| ASTM | 450 | 655 | 25 | – | 31 | 293 | – |

| JIS | – | – | – | – | – | – | – |

| GB | 450 | 620 | 25 | – | 31 | 293 | – |

| 2507 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRC ≤ | HBW ≤ | HV ≤ |

| ASTM | 550 | 795 | 15 | – | 32 | 310 | – |

| JIS | – | – | – | – | – | – | – |

| GB | 550 | 795 | 15 | – | 32 | 310 | – |

Product Description of perforated stainless steel sheet and plate

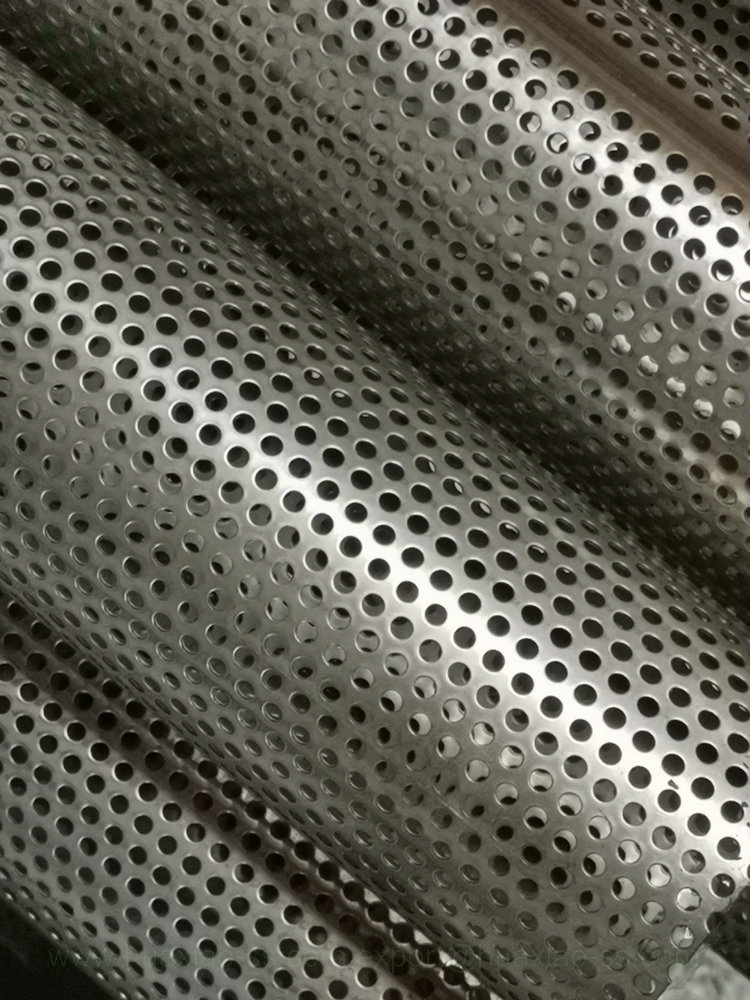

Perforated stainless steel plate is a sheet product made by processing on stainless steel plate, drilling, punching, cutting, and bending with a CNC punching machine according to the shape of the mold and slit. The product has a certain surface porosity and aesthetics and also has the characteristics of anti-slip, anti-fouling, and filtering. Therefore, it is widely used in construction, the chemical industry, environmental protection, energy, transportation, and other fields.

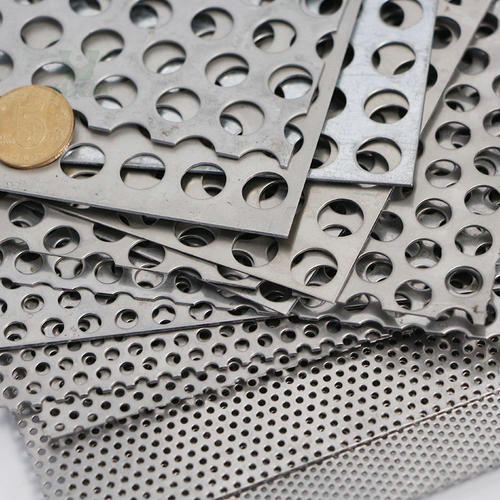

Perforated stainless steel sheets are available in many different hole diameters, hole types, and hole spacing, which can be selected according to different application requirements.

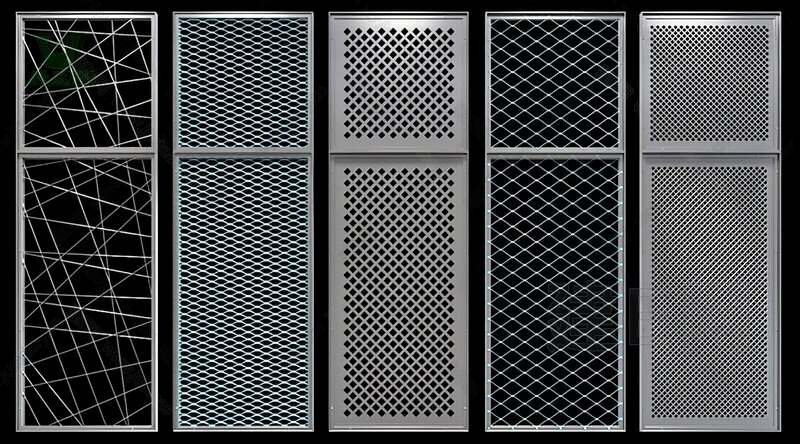

Different Types of Perforated Stainless Steel Sheets

Perforated stainless steel sheets can be divided into different types according to the shape of the hole, production process, application, and material.

Production Process of Perforated Stainless Steel Sheets

Material Preparation

Prepare the stainless steel plate, generally using cold-rolled sheets or hot-rolled sheets as raw materials.

Design Pattern

According to the design requirements or application scenarios provided by the customer, the design pattern of the perforated sheet is developed, including parameters such as hole diameter, hole spacing and hole type.

Punching

The sheet is punched by a punching machine to form holes of different shapes and sizes. The size and shape of the punched holes can be customized according to customer requirements.

Inspection and Packaging

After the above process, the stainless steel perforated sheet needs to be inspected to ensure that it meets the relevant quality standards, and then be packaged and shipped.

Cutting

According to the customer’s requirements, the stainless steel perforated sheet will be cut according to certain size to make it meet the use requirements.

Leveling and Polishing

Leveling, edge cutting, grinding, and polishing are required to ensure the surface of the stainless steel perforated sheet is smooth and without sharp edges.

Features of Perforated Stainless Steel Sheets

- Corrosion Resistance: Perforated stainless steel sheets inherit excellent corrosion resistance due to the superior material quality of stainless steel itself, enabling long-term use in various harsh environments such as damp and acidic conditions.

- Elegant Appearance: Perforated stainless steel sheets undergo special treatment on the surface, presenting a smooth and sleek appearance with a strong metallic texture, enhancing overall decorative effects to meet diverse aesthetic demands.

- High Strength: Manufactured from uniformly thick metal materials, perforated stainless steel sheets possess high strength and rigidity, capable of withstanding significant external forces, ensuring structural stability and safety.

- Low Thermal Expansion: Perforated stainless steel sheets exhibit minimal thermal expansion coefficients, maintaining stable shape and performance in environments with large temperature fluctuations, reducing the likelihood of deformation or cracking.

- Flexible Processing: Utilizing stamping techniques, perforated stainless steel sheets can achieve various perforation diameters and patterns to meet different application requirements in areas such as architectural decoration, filters, and security screens.

- Excellent Environmental Performance: Perforated stainless steel sheets are widely used in environmental noise control barriers, effectively reducing noise pollution and aligning with modern societal environmental requirements.

Application of Perforated Stainless Steel Sheets

Stainless steel perforated panels are widely used in various industries for noise management barriers in public facilities such as highways, railways, and subways, as well as for sound-reducing and absorbing panels in industrial buildings such as generator rooms and construction partitions. They can also be used as sound-absorbing materials for building ceilings and wall panels, as well as for decorative purposes in balconies, tables, and chairs.

Stainless steel perforated panels can also serve as protective covers for mechanical equipment, speaker grilles, and screens for grinding, mining, and feed operations. In addition, they are used as fruit baskets, food covers, and fruit bowls in kitchen equipment, as well as shelf nets in shopping malls and decorative exhibition stands. They can also function as ventilation and venting holes in grain storage and as filters for water seepage in soccer field lawns.

Other applications of stainless steel perforated panels include their use in food machinery sieve plates, decorative ceilings, tool case speakers, and filter sound absorption, among other equipment. They are available in lightweight, obscure round-net designs for use in pedal platforms, filters, and filter valves, and they can be shaped to fit various customer requirements.

Construction Industry

Stainless steel perforated sheet has a good decorative effect, anti-corrosion, durable performance, and sound-absorbing and acoustic characteristics, and can be used for the decoration of building facades, various fancy ceilings and partitions, doors, windows and railings, ventilation ducts, and sunshades

Automobile Industry

Stainless steel perforated sheet can be used for automobile interior, dashboard, door panel, luggage rack and other parts, beautiful and generous, reduce the quality of the body.

Home Decoration Industry

Stainless steel perforated sheets can be used for furniture, chandeliers, screens, flower shelves, etc., which can play the role of decoration and partition.

Machinery Industry

Stainless steel perforated sheets can be used as shields for various machinery and equipment, accessories for machinery and equipment (gaskets, spring seats, brackets, etc.), sieve plates for machinery and equipment (sieve plates for grain processing machinery, vibrating sieves, filters, and other equipment), cooler cover plates (air coolers, oil coolers), vibration plates (vibrating sieves, vibrating feeders and other vibrating equipment), sound insulation plates.

Machinery Industry

Stainless steel perforated sheet can be used to make sieves, sieve plates, sieve tubes, etc., with the function of filtering, sieving, grading, etc.

Stainless Steel Sheets Supplier — HUAXIAO

Perforated stainless steel sheets, with their unique characteristics of corrosion resistance, high strength, and elegant appearance, have become the preferred material in various fields. Whether in architectural decoration, noise control, or industrial applications, they demonstrate excellent performance and broad prospects.

As a company specializing in stainless steel production, Huaxiao Metal, with its rich experience and advanced technology, can provide customers with stainless steel perforated sheets in different sizes and patterns. We also accept personalized customization to meet diverse customer needs. We prioritize product quality and customer service, committed to providing customers with the highest quality products and the most satisfactory service.

Furthermore, to help customers better understand our products, Huaxiao Metal offers a free sample service. You only need to pay for shipping to receive our carefully crafted stainless steel perforated sheet samples, experiencing firsthand their outstanding quality and exquisite appearance.