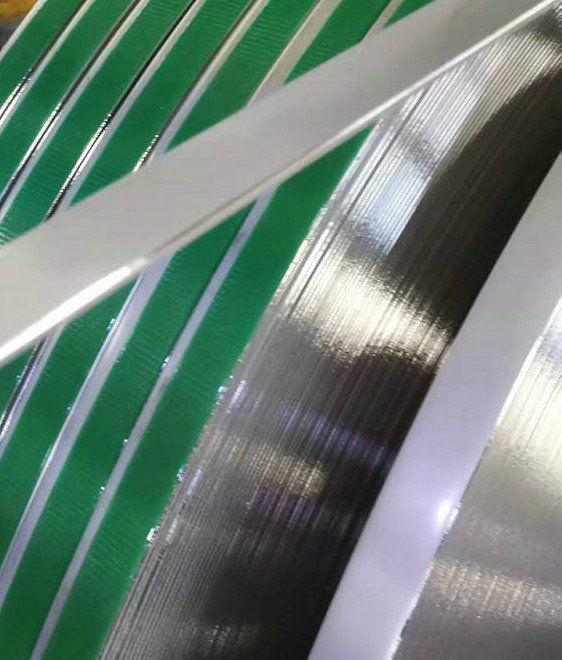

301 Stainless Steel Strips Supplier

- Thickness: 0.03mm – 1.5mm

- Width: 3mm – 600mm, the wider products pls check in coil products

- Finish: 2B, BA, TR

- TEMPER/Hardness: ANN / Soft, 1/2, 3/4, FH/Full hard, EH, SEH/Super EH

- Coil Diameter /ID: 200mm, 400mm, 510mm, 608mm

- MOQ: 2MT

Product Description of 301 Stainless Steel Strips

301 stainless steel strips are a high strength, high hardness stainless steel product, belongs to the austenitic stainless steel, its chemical composition contains 17% chromium and 7% nickel. 301 stainless steel strips have good corrosion resistance, high strength and hardness, good processing properties, and high-temperature resistance, so it is widely used in electronics, machinery, chemicals, construction, automotive, aerospace, and other fields.

301 stainless steel strips can be processed and formed by a variety of processing methods, such as cold processing, hot processing, cold drawing, cold rolling, etc., and can be made into a variety of shapes and sizes, such as springs, shrapnel, syringes, films, etc. 301 stainless steel strips also have good plasticity and machinability, easier to bend and deformation in the process, can be used to make complex shapes and structures.

Compared with other stainless steel products, 301 stainless steel strips have higher hardness and strength, as well as good corrosion resistance and high-temperature resistance, and can be used in harsh working environments, so it is widely used in areas requiring high strength and high hardness.

Product Range of 301 Stainless Steel Strips

Contents | Precision Stainless Steel Strip | Cold-Rolled Stainless Steel Strip |

Range Specification | 0.02≤Hardness≤0.5mm | Hardness≥0.3mm |

Thickness Tolerance | Thickness≤0.1mm ±2.5μm Thickness≤0.5mm ±5μm | Thickness≤0.6mm ±40μm Thickness≤1.0mm ±50μm |

Uniformity of Hardness | ±10HV | No requests |

Width Tolerance | Width≤30mm ±0.015mm Width≤100mm ±0.03 mm Width≤250mm ±0.05 mm Width≤610mm ±0.1 mm | Width≤1524mm +5mm |

Straightness | 1-2 IU | Min 3 IU |

The Burr Height and Edge Quality | Thickness 0.02-0.1mm ≤6% Thickness 0.1-0.5mm ≤5% There are special requirements for deburring or round-edged strip steel | Thickness 0.4mm Burr height 0.03mm Thickness 3.0mm Burr height 0.09mm No requests |

Specification of 301 Stainless Steel Strips

Chemical Composition of 301 Stainless Steel Strips

301 | C % | Si % | Mn % | P % | S % | Ni % | Cr % | Mo % | N % |

ASTM | 0.15 | 1.00 | 2.00 | 0.045 | 0.030 | 6.0-8.0 | 16.0-18.0 | – | 0.1 |

DIN/EN | 0,07 | 1,00 | 2,00 | 0,045 | 0,030 | 6,0-8,0 | 16,0-18,0 | – | 0,1 |

JIS | 0.15 | 1.00 | 2.00 | 0.045 | 0.030 | 6.0-8.0 | 16.0-18.0 | – | – |

GB | 0.15 | 1.00 | 2.00 | 0.045 | 0.030 | 6.0-8.0 | 16.0-18.0 | – | 0.1 |

Physical Property of 301 Stainless Steel Strips

| 301 | Density (g/cm³) | Melting point (℃) | Thermal conductivity (W/m-K) | Coefficient of thermal expansion (10^-6/K) |

| ASTM | 7.93 | 1400-1450 | 16.3 | 17.2 |

| JIS | 7.93 | 1399-1454 | 16.3 | 17.2 |

| EN | 7.9 | 1400-1450 | 16.2 | 17.2 |

| GB | 7.93 | 1398-1454 | 16.3 | 17.2 |

Mechanical Property of 301 Stainless Steel Strips

301 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | 205 | 515 | 40 | – | 95 | 217 | – |

JIS | 205 | 520 | 40 | 207 | 95 | – | 218 |

GB | 205 | 515 | 40 | – | 95 | 217 | 218 |

Features of 301 Stainless Steel Strips

301 stainless steel strips contains 17% chromium, which can effectively improve its corrosion resistance, so that it has good corrosion resistance in wet or corrosive environments.

301 stainless steel strips are relatively easy to bend and deform during processing, and can be processed and formed by cold working and hot working, with good plasticity and workability.

301 stainless steel strips have a high strength and hardness, can withstand large loads, while having good wear resistance.

301 stainless steel narrow strips have a high temperature resistance, can work in high temperature environment, not easy to deformation and burn damage.

Application of 301 Stainless Steel Strips

Electronics Industry

301 stainless steel strips can be used to manufacture battery cells, spring pieces, connectors, wires, motor coils, flat cables and other electronic components, but also for the manufacture of cell phone bracket, cell phone bezel, digital camera frame and other electronic accessories.

Mechanical Manufacturing Industry

301 stainless steel strips can be used to manufacture mechanical springs, mechanical seals, mechanical blades, mechanical parts, etc.

Chemical Industry

301 stainless steel strips can be used to manufacture chemical pipelines, chemical containers, chemical pumps, chemical valves, and other chemical equipment, and can withstand the corrosive nature of chemical substances, with high stability and durability.

Construction Industry

301 stainless steel strips can be used to manufacture building materials, door and window fittings, curtain wall decorative parts, roofing materials, etc., because of its high corrosion resistance, oxidation resistance, strength and hardness, so it is an ideal building material.

Automotive Industry

301 stainless steel strips can be used in the manufacture of automotive exhaust, automotive braking systems, automotive fuel tanks and other automotive parts, due to its high temperature resistance and corrosion resistance, so it can meet the automotive industry's high requirements for parts.

Aerospace Industry

301 stainless steel strips can be used for the manufacture of aerospace parts, engine components, aircraft structural materials, etc., due to its good high-temperature strength and high strength, high hardness characteristics, is an ideal aerospace material.

FAQ

301 stainless steel strips have good corrosion resistance, mainly thanks to its content of more than 17% chromium. Chromium can react with the oxygen in the air to form a dense chromium oxide film, covering the steel surface, thus preventing further corrosion of steel. In addition, 301 stainless steel strips also contains a certain amount of nickel, which can improve the steel’s resistance to oxidation and increase its corrosion resistance. Therefore, 301 stainless steel strips are widely used in many industries that require high corrosion resistance.

The hardness of 301 stainless steel strips are relatively high, generally between Rockwell hardness (HRC) 50-60, can resist a certain degree of wear and scratching. At the same time, 301 stainless steel strips have good elasticity and plasticity, can be under pressure when a certain degree of deformation and not easy to break. Therefore, 301 stainless steel strips are also widely used in applications requiring high hardness and strength, such as making springs, electronic components, and other fields.

301 stainless steel narrow strip has good processability and can be sheared, stamped, bent, stretched, formed, and other processing processes. The processability of stainless steel depends on factors such as the chemical composition of the steel, organizational structure, and processing conditions. For 301 stainless steel narrow strip, its chemical composition and heat treatment process control can make its organizational structure achieve better uniformity and stability and therefore has better processing properties. In addition, in order to improve the processing properties of 301 stainless steel narrow strips, heat treatment, cold working, tempering, and other processes can be used for processing.

There are a variety of surface treatment methods for 301 stainless steel narrow strips, the common ones include the following:

Mechanical Polishing: Mechanical cutting, grinding, and other ways to remove the surface roughness, so that the surface becomes smooth and bright.

Acid Cleaning Treatment: The use of an acidic solution for stainless steel surface treatment, can remove oxidation, rust, and other impurities so that the surface becomes smooth and clean.

Electrochemical Polishing: With the use of electrochemical principles of stainless steel surface polishing treatment, you can get high brightness and a good surface flatness effect.

Electroplating: A thin layer of metal or alloy is plated on the surface of stainless steel, which can improve the wear resistance, corrosion resistance, and aesthetics of the surface.

Coating: Coating a layer of the stainless steel surface, can play a role in beautifying the surface, anti-corrosion, etc.

Yes, as a professional stainless steel strips supplier, the size and thickness of our 301 stainless steel strips can be customized according to your specific needs. Generally speaking, the width of 301 stainless steel strips can range from a few millimeters to tens of millimeters, and the thickness can be customized according to the customer’s needs. In addition, the length of the 301 stainless steel strips is generally determined according to the factory’s production line and equipment, but if the customer has special requirements, you can also communicate and negotiate with the supplier in order to meet the needs of customers. It should be noted that the price of different specifications of 301 stainless steel strips will vary, and customers need to take full account of their own use needs and budget when choosing custom specifications.

The price of 301 stainless steel strips depends on several factors, including the cost of materials, production processes, specifications, quality standards, market supply, demand, etc. Generally speaking, the price of 301 stainless steel strip will be relatively stable but will be affected by market supply and demand and cost factors, and therefore will fluctuate. In addition, the price of custom specification 301 stainless steel strips may be higher compared to the regular specification, because it requires special products according to customer demand.

The exact price will also need to be determined based on the local market conditions and specific quotes from suppliers. If you need to know the price of 301 stainless steel strips, you can consult with Huaxiao stainless steel strips supplier. We are professional exporters of stainless steel products from China, and our high-quality products and services have been well received by our customers.

301 stainless steel strips and 304 stainless steel strips are two commonly used stainless steel strips materials, there are several major differences between them as follows:

Chemical Composition: 301 stainless steel chemical composition contains a higher element of carbon and a lower element of nickel, while 304 stainless steel, on the contrary, contains a lower element of carbon and a higher element of nickel. This makes 301 stainless steel has higher strength and hardness, but for some more corrosive environments, 304 stainless steel performs better.

Uses: Due to its high hardness and strength, 301 stainless steel is mainly used in applications that require high strength and wear resistance, such as electronics, electrical and automotive. 304 stainless steel, on the other hand, is more suitable for applications that require corrosion and high-temperature resistance, such as food processing, medical devices, and chemical installations.

Price: Due to the difference in material composition and usage, 301 stainless steel is usually a little cheaper than 304 stainless steel.

301 stainless steel strips and 316 stainless steel strips are two common stainless steel materials, and there are several major differences between them as follows:

Chemical Composition: 301 stainless steel chemical composition contains a higher element of carbon and a lower element of nickel, while 316 stainless steel, on the contrary, contains a lower element of carbon and a higher element of nickel and molybdenum. Therefore, 316 stainless steel has better corrosion resistance and high-temperature resistance for more severe environmental conditions.

Physical Properties: Due to the difference in chemical composition, the physical properties of 301 stainless steel and 316 stainless steel are also somewhat different, such as density, coefficient of thermal expansion, and thermal conductivity.

Uses: Due to its excellent corrosion resistance and high-temperature resistance, 316 stainless steel is mainly used in the marine environment and chemical industry and other fields that require a high degree of corrosion resistance. While 301 stainless steel is more suitable for applications that require high strength and wear resistance, such as electronics, electrical and automotive fields.

Price: Due to the difference in material composition and usage, 316 stainless steel is usually a little more expensive than 301 stainless steel.

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China