446 Stainless Steel Welded Tube Suppliers

Specification: SMLS 446 A268 3/4 SCH 40 – 38497, AISI 446, UNS S44600, ASTM A213 TP 446, HRS 446, SS 446/1.4762

Size Range: From 4mm4mm to 800mm800mm

Wall Thickness Range: From 1mm to 150mm (SCH10-XXS)

Length Options: 4000mm, 5800mm, 6000mm, 12000mm, or as required.

Finish: 2B, BA,4K,8K, NO.1,2D,3#, HL

Type: Round, square, rectangular, hexagonal, flat, angle

Technique: Cold rolled, hot rolled

Payment method: T/T, LC

Price: Inquiry Now

446 Stainless Steel Welded Tube Data Sheet

Chemical Components Of 446 Stainless Steel Welded Tube

| Element | Content (%) |

| Iron, Fe | 73 |

| Chromium, Cr | 23.0 – 27.0 |

| Manganese, Mn | 1.5 |

| Silicon, Si | 1 |

| Nickel, Ni | 0.25 |

| Carbon, C | 0.2 |

| Phosphorous, P | 0.04 |

| Sulfur, S | 0.03 |

physical properties Of 446 Stainless Steel Welded Tube

| Property | Value |

| Density | 7.80 g/cm³ / 0.282 lb/in³ |

| Thermal expansion co-efficient | 10.4 µm/m°C (0-100°C) / 5.78 µin/in°F (32-212°F) |

| Thermal conductivity | 21.6 W/mK / 150 BTU in/hr.ft².°F |

mechanical properties Of 446 Stainless Steel Welded Tube

| Property | Value |

| Tensile strength | 550 MPa (79800 psi) |

| Yield strength | 345 MPa (50000 psi) |

| Elastic modulus | 200 GPa (29000 ksi) |

| Poisson’s ratio | 0.27-0.30 |

| Elongation at break | 20% |

| Hardness, Brinell (estimated from Rockwell B) | 159 |

| Hardness, Knoop (estimated from Rockwell B) | 173 |

| Hardness, Rockwell A (estimated from Rockwell B) | 51.1 |

| Hardness, Rockwell B | 83 |

| Hardness, Vickers (estimated from Rockwell B) | 159 |

Product Description Of 446 Stainless Steel Welded Tube

446 stainless steel welded tubes stand out as highly effective ferritic alloys with exceptional heat and corrosion resistance. This makes them an excellent choice for applications demanding durability in challenging conditions. They offer remarkable formability and weldability, making fabrication easier. These tubes find their place in various industries, including automotive exhaust systems, industrial furnaces, gas burners, and kilns.

It’s important to note that, like other high-chromium ferritic stainless steels, 446 stainless steel has an embrittlement temperature at 885 °F. This information is crucial for ensuring the material’s performance in specific conditions.

In summary, 446 stainless steel welded tubes, sourced from Huaxiao stainless steel tube suppliers, offer a comprehensive solution for industries requiring heat and corrosion resistance, formability, and weldability in demanding applications subjected to high temperatures and challenging environments.

features Of 446 Stainless Steel Welded Tube

446 stainless steel welded tubes are engineered to withstand extreme temperatures, showcasing exceptional heat resistance in demanding environments. With the capability to endure temperatures ranging from 1500 to 2100 °F (815 to 1149 °C), these tubes provide reliable performance in applications involving elevated heat levels. This remarkable heat resistance makes them a preferred choice for industries such as automotive, industrial furnaces, and high-temperature processing, where stability and reliability under extreme thermal conditions are essential.

446 stainless steel welded tubes exhibit remarkable corrosion resistance, making them suitable for various challenging environments. While primarily a heat-resistant material, 446 stainless steel also offers good resistance against corrosion, especially in mildly corrosive atmospheres. This attribute expands its utility beyond high-temperature applications, making it a versatile choice for industries such as automotive, industrial furnaces, and chemical processing, where both heat and corrosion resistance are crucial factors for performance and longevity.

446 stainless steel welded tubes possess excellent formability, allowing them to be easily shaped and fabricated into various forms without compromising their structural integrity. This attribute is particularly beneficial in applications that require complex shapes, tight bends, or intricate designs. The material’s formability, combined with its other properties such as heat resistance and corrosion resistance, makes it a valuable choice for a wide range of industries, from automotive to architectural, where both functionality and aesthetics matter.

446 stainless steel welded tubes exhibit good weldability, which is crucial for various fabrication processes and joining methods. This material can be successfully welded using commonly used welding techniques such as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and shielded metal arc welding (SMAW). Its ability to maintain its integrity and mechanical properties after welding makes it suitable for applications where joining different components is necessary. Proper welding procedures and techniques should be followed to ensure the best results and maintain the material’s performance characteristics.

One of the standout features of 446 stainless steel welded tubes is their exceptional oxidation resistance, particularly at high temperatures. This property makes them well-suited for applications in environments where exposure to elevated temperatures and oxidative conditions is common. The alloy’s ability to resist oxidation helps maintain its structural integrity and prevents the formation of scales, which can compromise the performance of materials over time. This characteristic is particularly advantageous in applications such as industrial furnaces, gas burners, and other high-temperature equipment where maintaining material integrity is essential for reliable performance.

One of the unique advantages of 446 stainless steel welded tubes is their ability to tolerate contact with molten metals such as copper, lead, tin, and brass. Unlike many other stainless steel alloys, 446 stainless steel can withstand exposure to these molten metals without undergoing significant degradation or damage. This property makes it a preferred choice in applications where interactions with molten metals are part of the operational conditions. Industries like metal casting, metallurgy, and specialized manufacturing processes can benefit from this exceptional tolerance to molten metals, enhancing the longevity and performance of the material in demanding environments.

Application Of 446 Stainless Steel Welded Tube

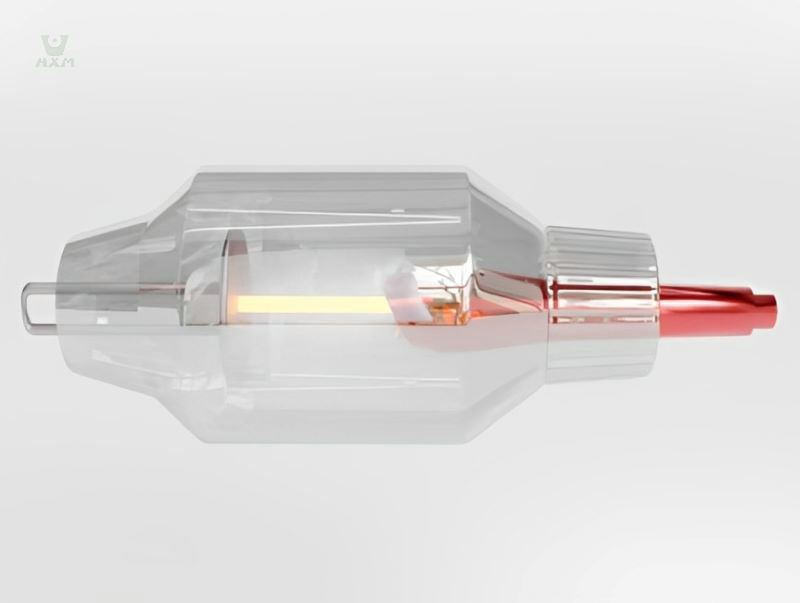

X-ray Tube Bases

446 stainless steel welded tubes are a vital component in X-ray tube bases, which are essential for the functionality of X-ray equipment. These tubes require materials with exceptional heat resistance and corrosion resistance due to the high temperatures and potential exposure to various chemicals. Partnering with reputable stainless steel tube suppliers ensures the availability of high-quality 446 stainless steel tubes for reliable and durable X-ray tube bases in medical, industrial, and scientific applications.

Oil Burner Components

446 stainless steel welded tubes play a crucial role in oil burner components, where they are exposed to extreme heat and potential corrosive environments. These tubes provide excellent heat resistance and corrosion resistance, making them a reliable choice for oil burner applications. Partnering with reputable stainless steel tube suppliers ensures access to high-quality 446 stainless steel tubes that contribute to the efficient and durable performance of oil burner systems in various industries.

Industrial Mufflers

446 stainless steel welded tubes are utilized in industrial mufflers to effectively dampen noise and reduce exhaust gases. Their high heat resistance and corrosion resistance properties make them ideal for this application, ensuring the longevity and efficiency of muffler systems. Collaborating with trusted stainless steel tube suppliers ensures access to top-quality 446 stainless steel tubes that contribute to the optimal performance of industrial mufflers across diverse sectors.

Kiln Linings

446 stainless steel welded tubes are integral in constructing kiln linings for various high-temperature processes, including ceramics, cement, and metal heat treatment. Their exceptional heat resistance and corrosion resistance make them a reliable choice for withstanding the extreme conditions within kilns. Sourcing these tubes from reputable stainless steel tube suppliers ensures the durability and longevity of kiln linings in industries that rely on efficient and consistent thermal processes.

Glass Molds

446 stainless steel welded tubes find valuable application in crafting glass molds used in the glass manufacturing industry. These tubes, sourced from reliable stainless steel tube suppliers, contribute to the creation of molds that can withstand the high temperatures and thermal shocks involved in glass forming processes. The superior heat resistance and corrosion resistance properties of 446 stainless steel make it a suitable material for ensuring the durability and precision of glass molds, ensuring consistent production qua

FAQ

Yes, 446 stainless steel is suitable for high-temperature applications. It is known for its exceptional heat resistance, making it a preferred choice for industries such as automotive, industrial furnaces, gas burners, and kilns. Its ability to withstand temperatures up to approximately 2100 °F (1150 °C) without significant loss of mechanical properties makes it well-suited for environments with elevated temperatures.

Yes, 446 stainless steel is magnetic. It falls under the ferritic stainless steel category, which generally exhibits magnetic properties due to its crystal structure. This magnetic characteristic is a common trait of ferritic stainless steels, including 446 stainless steel.

Yes, custom sizes and lengths are often available for 446 stainless steel welded tubes. Huaxiao stainless steel tube suppliers can offer a range of options to meet specific project requirements, ensuring the tubes fit the intended application seamlessly.

Yes, 446 stainless steel can be welded using various welding techniques, including processes like TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and shielded metal arc welding (SMAW). It’s important to follow proper welding procedures and use appropriate filler materials to ensure the best results and maintain the corrosion resistance and mechanical properties of the material. Consulting with experienced welders and stainless steel tube suppliers is recommended for successful welding of 446 stainless steel.

One of the main differences between 446 stainless steel welded tubes and other stainless steels is its exceptional high-temperature oxidation resistance. Unlike many other stainless steel grades, 446 stainless steel demonstrates remarkable stability and performance at elevated temperatures, making it suitable for applications in environments where oxidation is a concern, such as in industrial furnaces, exhaust systems, and high-temperature processing equipment. This sets 446 stainless steel apart as a reliable choice for applications requiring resistance to extreme heat conditions.

446 stainless steel is a ferritic stainless steel with excellent oxidation resistance at high temperatures. It contains higher chromium content compared to many 400-series stainless steels, which imparts its outstanding heat resistance. This makes 446 suitable for applications involving extreme heat, such as industrial furnaces, exhaust systems, and kilns. Additionally, 446 stainless steel possesses better corrosion resistance in certain environments than some 400-series stainless steels.

On the other hand, the 400-series stainless steels, like 430 and 410, are also ferritic stainless steels but are not specifically designed for high-temperature applications. They generally have lower chromium content and are often used for less demanding applications, such as decorative purposes, kitchenware, and mild corrosive environments.

In summary, the key difference is that 446 stainless steel offers superior resistance to high-temperature oxidation, making it suitable for extreme heat applications, while 400-series stainless steels have varying levels of corrosion and heat resistance and are more commonly used for different purposes.